A 50-day activity in 2 days!

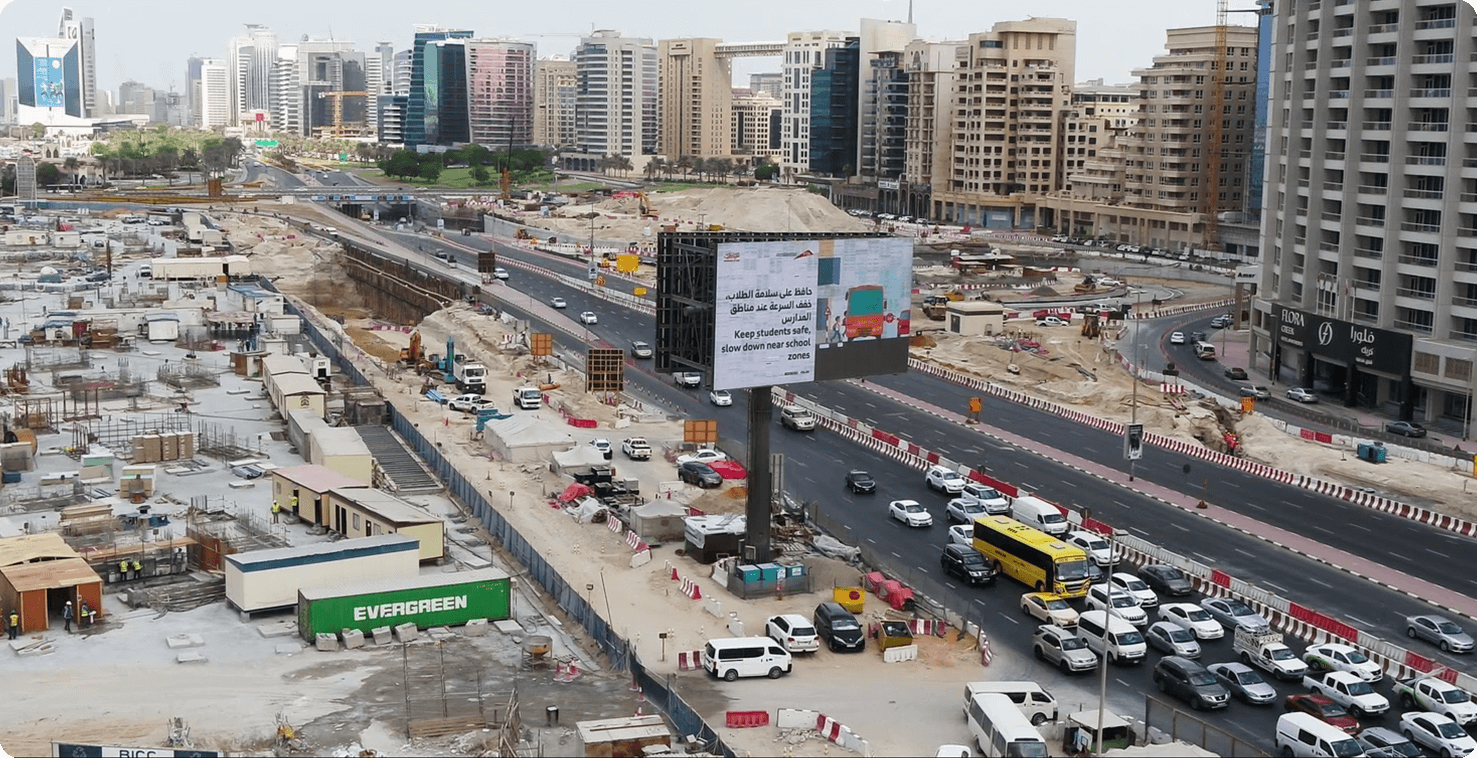

The Entrances to the Jewel of the Creek Development is one of Dubai’s most-anticipated large-scale road projects. It seeks to provide access to the landmark architectural masterpiece on the shores of Dubai Creek via new roads and underpasses on the busy Baniyas Road and Al-Ittihad Road.

Afcons was entrusted this project by Roads & Transport Authority (RTA) of Dubai. Among the most challenging activities of the project was relocating a 54-ton unipole, something never attempted in the UAE before. Anand Varadharasan, Deputy Project Manager, recounted that the critical activity seemed like an impossible task at one point.

“The 16m unipole on R4 ramp, with LED screen size of 16mX8m, needed to be shifted 150m from its original location, to construct an underpass. The bigger challenge: It had to be done in just 12 days!” said Varadharasan.

The RTA contract mandated if the relocation was to extend beyond the stipulated time, Afcons would be liable to bear the additional compensation towards revenue loss to the advertising company. As is RTA’s practice, the entire assembly, including LED screen had to be dismantled and reassembled at the new location. Since the unipole was adjacent to a highway, shifting could be possible only at night. The RTA had warned Afcons against any damage, which made Afcons liable to pay DHS 4 million.

Typically, an activity like this would take approximately 50 days.

How Afcons made it possible:

The JOC project team undertook a detailed analysis of the unipole and ascertained if it could be lifted as one unit instead of dismantling. A task force was formed to handle the activity efficiently. “Once confirmed by the team that the unipole could be moved in its totality, a four-day trial was held to minutely plan every aspect of the relocation. Afcons also had to pay DHS 3 million as guarantee for the operation. The stakes were tremendously high with no second chances,” said Varadharasan.

A temporary road was built, and a new foundation laid at the new location to set up the unipole. A 285-tonne crawler crane was brought to lift and move the 54-ton structure to its new location. This had to be done with minute precision, and the most critical aspect was measuring the accurate centre of gravity (CG) for the crane lift and maintaining it throughout the shifting process. “Maintaining the CG was crucial as there was no scope for the unipole to rotate or tilt. If it did, the result would be catastrophic. Also, any unguided movement would totally damage the LED panels, making Afcons liable to exorbitant fines,” he added.

The team, however, stuck to their guns and through the gruelling trial days, established the CG accurately. A specialised operator was deployed to manoeuvre the crawler crane. A measured distance was maintained, and accurate adjustments made while lifting the unipole to prevent it from touching the wall.

There were 64 bolts at the foundation base of the unipole’s new location, all of which were built with exact precision. The planning was so accurate that there was no deviation from the point the structure was dismantled to the point it was reinstalled. The markings and the measurements were so accurate that the unipole was repositioned and fitted in just one movement.

And all this was done in just two days!

“The operation spared the advertising agency significant losses, and Afcons was awarded an appreciation letter for their tremendous success. The team’s conviction in their engineering knowledge and their courage to implement against all odds made the impossible, possible,” concluded Varadharasan.

What are unipoles?

Unipoles are large-format billboards for purposes of digital advertising, placed atop very high poles. Their effectiveness is enhanced by the fact that are visible from long distances. There are two options when it comes to illumination: This can either be a light box or front-lit for versatility. The screen is generally built of hundreds of small LED fragile panels.